Ygm Series High Pressure Roller Raymond Grinding Mill Fine Powder Milling Equipment Limestone Gypsum Dolemite Raymond Mill Price

Description

Basic Info

| Model NO. | YGM65, YGM75, YGM85, YGM95 |

| Type | Raymond Mill |

| Motor Type | AC Motor |

| Motor Power | 37kw |

| Rotationl Speed | 13-15r/min |

| Application | Mine |

| Materials | Gypsum, Limestone, Granite, Dolomite, Carbonate |

| Condition | New |

| Warranty | 12 Months |

| After-sales Service | Forever All Over The Workd |

| Raw Material | Limestone, Gypsum, Dolomite, Quartz |

| Factory Visit | Welcome |

| Applicable Industries | Building Material Shops, Energy & Mining |

| Video Outgoing-Inspection | Provided |

| Capacity(T/H) | 1-50 T/H |

| Quality | Advanced Technology |

| Feature | Low Cost |

| Online Service Time | 7days *24 Hours |

| Category | Grind Mills in China |

| Original Place | Zhengzhou, Henan |

| Roller No. of Raymond Mill | 3/4/5 PCS |

| Max Feeding Size of Raymond Mill | 25mm |

| Spare Parts | Longlife Supply |

| Raymond Mill Custome Site | Could Visit |

| Certification | CE & ISO |

| Transport Package | Standard Container |

| Specification | Refer to per model |

| Trademark | Baichy |

| Origin | Zhengzhou, China |

| HS Code | 847420900 |

| Production Capacity | 50 Set / Month |

Packaging & Delivery

Package size per unit product 1120.00cm * 853.00cm * 969.00cm Gross weight per unit product 18000.000kgProduct Description

YGM Series High Pressure Roller Raymond Grinding Mill Fine Powder Milling Equipment Limestone Gypsum Dolemite Raymond Mill Price

Product Description

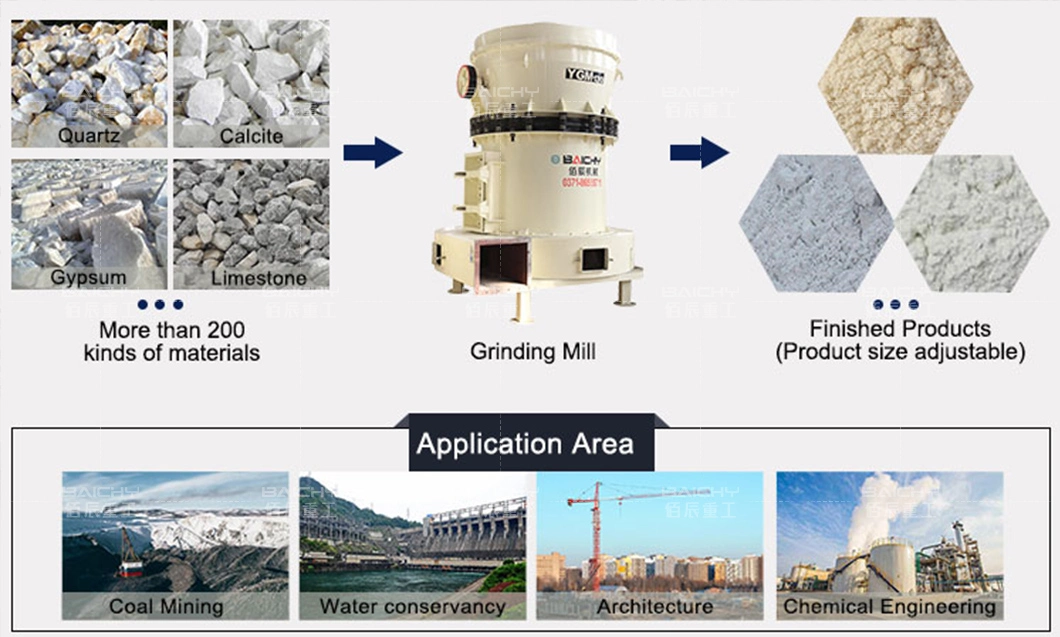

YGM high pressure Raymond grinding mill is improved on the basis of R series Raymond mill. Through high pressure spring pressure, increasing the grinding roller centrifugal force on the material grinding pressure.YGM raymond mill is especially suitable for processing Mohs hardness level 7, humidity below 6% of all kinds of non-flammable and explosive minerals, such as barite, limestone, ceramics, slag and other materials of fine powder processing. The particle size of the finished product is adjusted in the range of 80-425 mesh. The particle size of the material ground by the Raymond mill is relatively fine and uniform, and the finished product can well meet the material requirements of various fields.

Baichy Raymond Mill Features

1.Small footprint, strong systemicVertical structure, small footprint, systematic, from raw materials roughing to transport to the milling to packaging, forming an independent production system. 2. Good stability, high reliabilityMainframe gearing adopts sealed pulley and gear box, smooth transmission , reliable operation. Core parts of Baichy Raymond Mill are made of high quality castings and extrusions , sophisticated technology and rigorous process to ensure that the durability of the equipment.3. Good product size , through screening rate is 99%Electrical system adopts centralized control, grinding mill workshop is basic enable unmanned operation. Compared with other milling equipment, through screening rate is 99%.

Product Parameters

| Model | Roller No. | Roller Size (mm) | Grind Ring Inner Dia. Height & Length(mm) | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| YGM65 | 3 | 210×150 | 650×150 | ≤ 15 | 0.613-0.033 | 0.4-1.8 | 15 | 4100×3300×4500 |

| YGM75 | 3 | 260×150 | 780×150 | ≤ 15 | 0.613-0.033 | 1-3 | 18.5 | 4300×3500×5100 |

| YGM85 | 3 | 270×150 | 830×150 | ≤ 20 | 0.613-0.033 | 1.2-4 | 22 | 5300×4100×5200 |

| YGM85B | 3 | 270×150 | 830×150 | ≤ 20 | 0.613-0.033 | 1.2-3.5 | 22 | 5300×4100×5200 |

| YGM95 | 4 | 310×190 | 950×190 | ≤ 25 | 0.613-0.033 | 2.1-5.6 | 45 | 7100×5900×7900 |

| YGM130 | 5 | 410×230 | 1280×230 | ≤ 30 | 0.613-0.033 | 2.5-9.5 | 90 | 7900×8000×9700 |

| YGM160 | 6 | 450×300 | 1600×300 | ≤ 35 | 0.613-0.033 | 8-16 | 132 | 12550×5700×8355 |

| YGM190 | 6 | 500×330 | 1900×330 | ≤ 40 | 0.613-0.033 | 18-36 | 250 | 11200x8530x9685 |

Raymond mill working principle

YGM Raymond mill is high pressure grinding mill composed by main grinding machine, fineness analysis machine, blower, cyclone, bag dust collector and connecting air duct. According to user needs, Baichy machinery could supply jaw crusher, bucket elevator, vibrating feeder, electric control cabinet and other auxiliary equipment.How does YGM raymond mill machine work?In YGM raymond mill frame, a 1000-1500kg high pressure spring is fixed to the roller suspender. After the grinder is put into effect, the ring affected by the high pressure spring and centrifugal force. And its rolling pressure is 1.2 times higher than that of the Raymond grinder under the same power condition and the output is raised to higher degree. When materials loaded into the grinding cavity. It is shoveled into the space between the roller and the ring for grinding. The being grinded powder is routed to the classifier along the circulation wind of the blower. Qualified fine powder is guided to the cyclone collector as final product and large size powder falls back to the grinder for regrinding. There is a powder locking equipment under the cyclone in raymond vertical grinding mill , which isolates the outside positive air pressure and the negative air pressure inside cyclone. And this ensures high productivity. In addition, the residual air and dust under the main unit will be transferred to dust catcher equipment through pipes and be cleaned there. The clean air will be discharged so that environment will be protected.

Detailed Photos

Baichy is gradually expanding its business market depending on quality performance and service support. Through the international mining machinery exhibitions, professional equipment, technology and good service to customers in kinds of countries.<<< Baichy Raymond Mill Plant Case >>>

We offer a package service-foundation construction, equipment installation, device testing and operation guidance. Whether warranty expires, we will supply timely and thoughtful on-site maintenance.We give you operation training on customer site to let end-users know how to reduce repair times, prolong usable life of equipment and improve efficiency. Moreover, we will teach end-users to know the structure design, working principle, basic maintenance and fault treatment methods.

| Limestone grinding mill plant Material : LimestoneMax feeding size : 25mmOutput size : 300meshCapacity : 8-10 ton per hour | Dolomite grinding mill plant Material : Dolomite rockMax feeding size : 250mmOutput size : 250meshCapacity : 3-5 ton per hour | Gypsum mill plant Material : GypsumMax feeding size : 200mmOutput size : 325meshCapacity : 10-15 ton per hour |

Baichy headquarters is located in the industrial park in Jiaozuo City. It covers a total area of 200,000 square meters, including 150,000 square meters of standarized workshop. There are more than 200 sets of various large and medium-sized metal processing lathe, riveting machine, welding equipment and assembly equipment. We have more than 500 workers, including more than 20 middle and senior technicians. Baichy is mainly focus on 4 series products: stone crusher machines, sand making equipment, powder grinding mills, mineral processing equipment and their spare parts. Every year, Baichy can turn out 1,000 sets of crushers and 10,000 tons of crusher parts.

FAQ

1. Are you manufacture or trading company?We are factory, established in 2003.2. How long is your delivery time?7-10 days for the stock, 15-30 days for the mass production.3. What is your payment method?30% deposit in T/T advance, 70% balance before shipment.4. How long is the warranty? Does your company supply the spare parts?One year. Spare parts for you at lowest cost.5. If I need the complete crushing plant can you help us to build it?Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Prev: Perfect Lubrication System Cone Crushing for Mine/Coal

Next: Vixon Cone Crusher Vih/Vis Series Single Cylinder Hydraulic

Our Contact