RF1700 Vertical Roller Mill

Description

Basic Info

| Model NO. | RF1700 |

| Condition | New |

| Warranty | 13 Months Since The Date of Bl |

| After-sales Service | Engineers Are Available for Oversea Service |

| Transport Package | Shipping Standarded Package |

| Trademark | Ruifeng |

| Origin | Yingkou City Liaoning Province China |

| HS Code | 84742020 |

| Production Capacity | 30 Sets/Year |

Product Description

RFLM SERIES ULTRAFINE VERTICAL ROLLER MILLEquipment introduction

RFLM series ultrafine vertical roller mill is an ultrafine vertical roller mill researched and developed by Ruifeng Powder Equipment based on years of experience and in-depth research on powder processing technology, it is able to process ultrafine powder that requires secondary classification in the past in one time, reducing energy consumption by 35% and above, minimizing the inventory of coarse powder requiring secondary classification, and lowering raw material cost; through continuous optimization and improvement of various parts, the vertical mill is possessed with high reliability and extremely low downtime, and is widely applied in the field of large-scale processing of ultrafine powder including calcite, barite and talc.

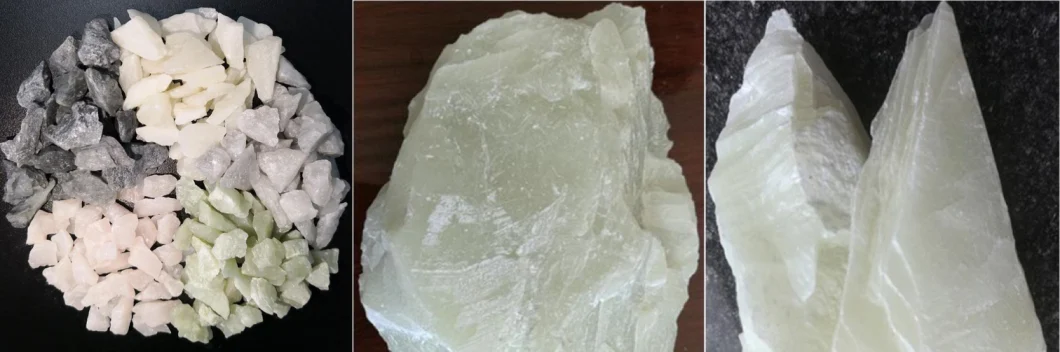

Fit for material

Calcite, talc, graphite, gypsum,orthoclase, plagioclase, quartz, dolomite, fluorite, apatite, malachite, corundum, siliceous limeston, garnet, mica, sericite, bentonite, aluminum, maifanite, brucite, dolomite, barite, river pebble, granite, basalt, quartz, iron ore, diabase, limestone etc.

Machine working principle

The main motor drives the grinding disc rotating through the reducer, and materials are fed to the main unit of the roller mill through the screw conveyor and fall onto the center of the grinding disc under the action of gravity, at the same time, the air generated by the blower enters the roller mill through the air inlet Under the action of centrifugal force, materials move evenly from the center to the edge of the grinding disc; when passing through the roller way on the grinding disc, large material blocks will be crushed by the grinding roller, while fine materials will be compacted and form a material bed for inter-particle crushing. Crushed materials will continue to move to the edge of the grinding disc until being blown upward by the air jet guided by the nozzle ring around the grinding disc, while coarse materials will fall back to the grinding disc under the action of gravity for secondary grinding; fine materials carried by air flow wi enter the the classification system above the main unit for screening and classification. With the classification rotor blades working, coarse materials will be unable to pass through and fall onto the grinding disc for regrinding, while qualified fine powder will be carried by the air flow, move out from the classification system, and enter the dust removal system through an external pipeline; by passing through the dust remover, the materials will be separated from the air flow and collected as finished products. Besides, during grinding, debris contained in the material and large grain-size material will be separated and discharged to the slag discharge port by the scrapper, so as to ensure the quality of finished products. In addition, the pressure of the grinding roller can be adjusted by regulating the pressure of the hydraulic system, so as to adapt to different materials with different hardnesses; by adjusting the rotor speed of the multi-rotor classification system, the fineness for classification screening can be adjusted, so as to obtain qualified finished products of different specifications.

Mill Working Flow

1. Raw material belt conveyor2. Raw material hopper lifter3. Raw material conveyor4. Raw material conveyor5. Vertical roller mill main unit6. Dust collector7. Pneumatic conveyor8. Blower9. Verical roller mall finished product silo10. Quadratic calssifier raw material silo11. Classifier12. Dust collector13. Blower14. Quadratic classifer coarse powder silo15. Quadratic classifer fine powder siloProduct Parameters

Technical parameters of RFLM series roller mills| Technical parameter\ Model | RFLM1000 | RFLM1300 | RFLM1700 | RFLM2200 |

| Power of main unit (KW) | 200 | 280 | 450 | 800 |

| Power of blower(KW) | 160 | 200 | 315 | 630 |

| Power of air compressor(KW) | 22 | 30 | 45 | 75 |

| Power of classifier(KW) | 15x5 | 15x6 | 15x8 | 15x15 |

| Number of classifier wheel (pcs) | 5 | 6 | 8 | 15 |

Our Advantages

1. Machine can be customized. We design our vertical roller mills based on the specific needs of our users as well as the characteristics of materials to be processed, so as to meet the actual requirements of our users, such as calcium carbonate vertical roller mill, talc vertical roller mill, barite vertical roller mill, magnesium oxide vertical roller mill, magnesium hydroxide vertical roller mill, aluminium hydroxide vertical roller mill, magnesium carbonate vertical roller mill. --------------------------------------------------------------------------------------------2. Produce various particle size range RFLM series roller mill is configured with the latest mult-rotor classifer, which ensures large particle size range, 30%-30% for 2μm section, D97=4-45μm, specific surface area: 20000CM2/G, the roller mill can produce products with D97=4.0μm directly and reliably. --------------------------------------------------------------------------------------------3. High production capacity, lower vibration and noiseOptimized and improved grinding wheel, grinding disc, flow guide system and internal circulation system ensuring high grinding efficiency, and the output is 10~20% higher than that of a conventional vertical roller mill, and with lower vibration and noise.---------------------------------------------------------------------------------------------4. Multiple measures to save operating costsMachine each part adopts International brand. Classifier wheels of the vertical roller mill are made from wear-resistance materials, thermal treatment technology are adopted, ensuring long service life; the wear parts of grinding wheels and grinding discs are made from wear-resistance alloy, which ensures long service life under sever wear condition in the field of barite and talc processing, reducing wear parts replacement costs, and minimizing maintenance downtime for users. --------------------------------------------------------------------------------------------5. Intelligent. PLC control and touch screen operation are used, and automatic operation of the vertical roller mill production line is realized, operation data including speed, temperature, pressure, and pressure difference can be displayed and saved in a real time manner. Besides, automatic feeding according to the pressure, pressure difference, current and other data collected at each point is realized. Automatic operation has simplified the complex vertical mill operation. In addition, through Internet connection, remote control, remote trouble analysis and troubleshooting, and data analysis can be realized. RFLM Vertical Roller Mill Production Process Flow Chart.Besides the above advantages, Ruifeng Vertical roller mill also has many other advantages.If you are interested, pls contact us for more details.

After Sales Service

By summarizing years of production experience and customer's field feedback, our company has established a complete and effective service system and has bult an experienced service team for providing our users with technical guidance on powder production, as well as on-site equipment installation and commissioning services, and field operation guidance.

Packaging & Shipping

Prev: 5-200t/D Complete Electric Maize Corn Flour Roller Grinding Mill Machine Line Price

Next: 4.2X13m Wet & Dry Clinker Cement Limestone Mining Slag Grinding Ball Mill

Our Contact