Raymond Roller Mill Machine for Ore Powder Grinding

Introduction of Raymond Mill Fineness: 30-425mesh Capacity: 1-20t/h Raw materials: gypsum, talc, calcite, limestone, mar

Description

Basic Info

| Model NO. | YGM |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Technical Support |

| After Sale | Abroad Engineer |

| Color | as Request |

| Transport Package | Wooden Bo≃ |

| Specification | ISO900&⪞ apdot; &CE |

| Trademark | Clirik |

| Origin | Shanghai |

| HS Code | 84742090 |

| Production Capacity | 50 Sets Per Month |

Product Description

Introduction of Raymond MillFineness: 30-425mesh

Capacity: 1-20t/h

Raw materials: gypsum, talc, calcite, limestone, marble, barite, dolomite, granite, kaolin, bauxite, fly ash , oxidation iron oxide red, iron ore, etc.

Application of Raymond mill

Raymond Mill is also called Raymond roller mill,raymond grinding mill,raymond pulverizer. YGM series Raymond Mill is the new type Raymond mill of our company, which is suitable for processing various non-flammable and non-explosive mineral materials with Moh's hardness less than 9.3 and humidity less than 6%. It is widely used in the fields of metallurgy, construction, chemical industry, mining, highway construction etc,. The granularity of the finished powder size can be adjusted between 30 and 425 mesh. Examples of processing materials include quartz, feldspar, barite, calcite carbonate, limestone, talc, ceramic, iron ore, carborundum, bauxite, rock phosphate, coal and other materials, about 400 kinds of materials in total.

Technical Advantages of Raymond mill

1.Compared with the ball mill, the Raymond mill has higher efficiency, lower power consumption, smaller covered area, less investment.

2.The grinding roller compressed on the grinding ring tightly due to the centrifugal force.

3.The output and fineness of the finished product will not be affected when the grinding ring is worn to a certain degree.

4.The grinding roller and the grinding ring have a long replacement period, so it gets rid of the shortcoming that the wear parts of centrifugal mills have a short replacement period.

5.The classifying airflow of the Raymond mill flows according to the recycling process as: the fan mill shell cyclone separator the fan.

6.Compared with the high speed centrifugal grinder, there is less powder dust, and the operation room is clean without any pollution.

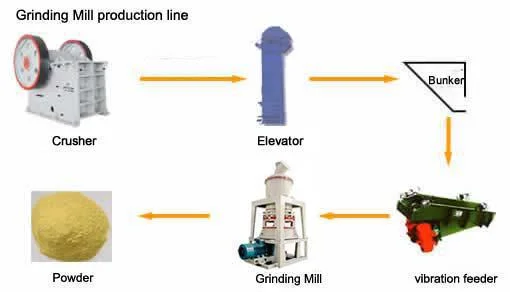

Raymond mill Working principle

Raymond mill is mainly composed of main unit, analyzer, fan, dischargeing cyclone separator, powder cyclone separator and air duct. Among them, the main unit consists of frame, blow shell, shovel, grinding roller and grinding ring.

1.The lump material will be conveyed into the storage bin by the bucket elevator after it is crushed into the required particle size by the jaw crusher.

2.Then electro vibrating feeder will uniformly transfer the material into the grinding chamber of the host machine.

3.The material is up thrown and fed into the space between the grinding roller and grinding ring in the process of synchronous rotation of the shovel and the grinding roller, and forms a cushion material layer.

4.The material on this layer is grinded between the grinding roller and the grinding ring. Thus, the purpose of powder production is achieved.

5.The grinded powder will be carried by the airflow of the fan into the analyzer for classification.

6.The powder with the qualified fineness will enter the large cyclone collector, together with the airflow through the pipes, for classification, and then, will be discharged by the discharging device, as the finished product.

7.The airflow is sucked into the air blower through the air return pipe on the upper part of the large cyclone collector.

8.The unqualified powder will be thrown to the external wall by the airflow and separated from the airflow.

9.The coarse powder will fall into the grinding chamber for regrinding due to its own gravity.

10.The whole airflow system is closed and cyclic, and it flows under the positive and negative pressure circularly.

Raymond Mill Parts

The main parts of Raymond mill is grinding roller, grinding ring, grinding roller assembly, the plum flower frame, air flue, coupling, perching knife and so on.

Technical Data Of Raymond Mill

| Type | Roller | Max. feeding size(mm) | Fineness(mm) | Output(t/h) | Power(kw) | Size(mm) | ||

| No. | Dimension(mm) | Height(mm) | ||||||

| YGM7815 | 3 | 260 | 150 | 15 | 0.613-0.033 | 1-3 | 18.5 | 4300*3500*5100 |

| YGM8314 | 3 | 270 | 140 | 20 | 0.613-0.033 | 1.2-4.6 | 22 | 5300*4100*5200 |

| YGM9517 | 4 | 310 | 170 | 25 | 0.613-0.033 | 2.1-5.6 | 37 | 7100*5900*7900 |

| YGM4121 | 5 | 410 | 210 | 30 | 0.613-0.033 | 2.8-10.5 | 75 | 9200*7250*9700 |

| MTM1600 | 6 | 440 | 270 | 35 | 0.613-0.033 | 5-20 | 132 | 12550*5700*8350 |

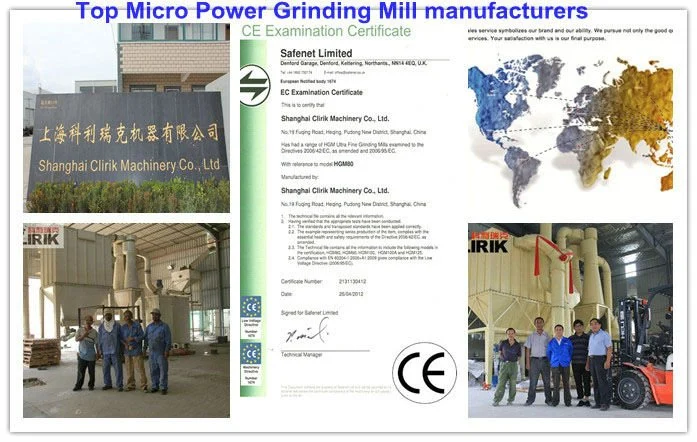

Raymond Mill Manufacturers

Shanghai Clirik Machinery, 25 years on Raymond mill producing. You are alwyas warmly welcomed to contact or visit us .Our engineers will design the most suitable solution for your project.

If you want to know the Raymond mill price,please leave you email and tel,We wlll send the raymond mill details and price.

Phone: 0086-21-20236178

Services to be enjoyed when purchasing grinding equipment:

Pre-sale service: 1.Clirik provides a variety of mining equipment for you to choose from. 2.Clirik will recommend suitable production lines and grinding equipment to you according to your site. 3.Clirik customizes the logo and color of the grinding equipment according to your company image. 4.Clirik provides third party inspection to ensure the quality of your grinding equipment. After-sales service: 1. Clirik provides you with online installation and use videos. 2. Clirik will provide you with technicians to install and debug the grinding equipment. 3. Clirik trains you the technicians who use and maintain the grinding equipment. 4. Clirik provides you with a one-year warranty and lifetime service for the grinding equipment.

Other Product Offered

| Ultrafine vertical Roller Mill | Micro Powder Grinding Mill | Coating Machine |

| Finished Size: 600-4500(mesh) Capacity: 3-20(t/h) Pass rate: D50 2 micron | Finished Size: 300-2500(mesh) Capacity: 1-45(t/h) Pass rate: D97 5 micron | Used to stone powder modification machine |

Our Contact

Send now